Engine Hourly Operating Cost & Its Impact On Aircraft Value

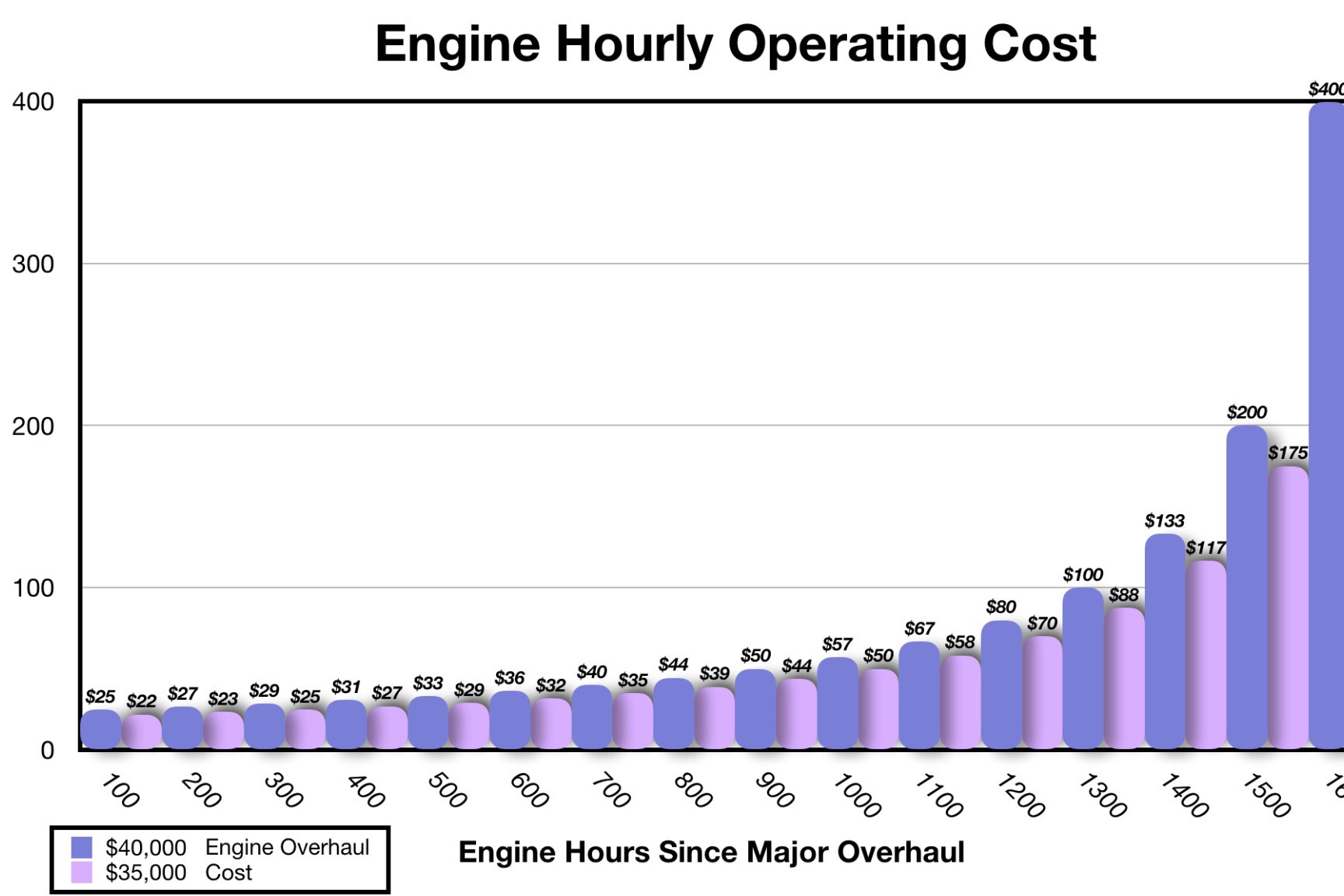

Before you decide to purchase that used aircraft with the high time engine, a glance at this chart and understanding the psychology of the typical aircraft buyer will quickly put the financial impact of your anticipated purchase into perspective.

I never really grasped the whole concept of exponential growth when I was a student and I didn't think there would be a practical application for the math until I started looking at the ownership and operating costs involved in an airplane engine.

For those of you thinking about purchasing an airplane, one of the biggest operating expenses you may encounter will be the cost of overhauling your airplane's engine. If controlling the operating cost of your airplane and managing its value are important to you, you need to understand how remaining engine life impacts both of these factors and how to manage them effectively.

My customers have heard me talk about having an aircraft exit strategy for a long time... about buying an airplane that makes sense on paper or, as I like to say, buying a good "paper airplane." Well, the most significant component of the any aircraft exit strategy involves the value of remaining engine life on the aircraft.

Some people may look at the reduced price of an airplane with a high time engine as a value in purchase terms. When comparing airplanes, they may look at an airplane with an 1,100 SMOH engine and a price point $15,000 less than a comparable airplane with 100 SMOH and think they are saving thousands upon purchase, when in fact, nothing could be further from the truth. Let me explain...

First, when it comes to properly assessing the value of the remaining engine life of your airplane's engine, the "books" are wrong. Both Vref and Aircraft Bluebook "straight line" the remaining engine value over the rated TBO time. So, if you fly an airplane with a 1,700 TBO IO550-B and the cost to overhaul that engine is estimated at $40,000, divide the $40,000 cost by the 1,700 hour TBO and you get about $23.53 an hour to amortize the cost of your engine overhaul. This is called the engine reserve amount and its a component of the variable operating expenses for any airplane, whether piston or turbine.

Logically, this methodology makes sense... but in reality, its way off. As they say, "perception is reality," and when it comes to aircraft buyers, most will perceive a 300 hour (SMOH) engine as "almost new" and a 1,400 hour (SMOH) engine as "almost run out." So you need to understand what this means in terms of the airplane's value and to you as the owner which is essentially that the first 300 hours and the last 300 operating hours of engine life have little impact on the value of engine life remaining. In other words, they are basically free engine hours.

Which brings us to the second component in managing your aircraft's value and that, simply put, is it's use. Let's say you have an opportunity to buy two identical airplanes, one with 250 hours SMOH, the other with 1,050 SMOH. Buying the airplane with the higher time engine will save you about $19K because the straight line value of this time is $18,800 at $23.53 an hour. So, if you fly 80 hours a year, and run your numbers out five years, the lower time engine will be at 650 hours SMOH, or 200 hours below mid-time, which by the way is the best point to sell any airplane. Applying the same use numbers to the higher time engine puts the engine total time SMOH at 1450... or "runout" in terms of airframe value. The low time engine cost you $23.23 an hour to operate for a total engine reserve expense of $9,412 while the same 400 engine hours on the high time engine brought the total engine time to a point where it is perceived at runout. If you amortize the $40,000 cost of an engine overhaul over 400 operating hours, the real hourly operating cost was $100. or 425% higher. Furthermore, the $19,000 cost savings you realized on the front end of the acquisition is now a net $21,000 liability.

One aircraft is salable and will command maximum value, the other requires a hefty investment for which both Aircraft Bluebook and Vref valuation books will give you less than half of what you invest to the overhaul the engine. Additionally, these valuation services do not recognize the costs of accessory overhauls, R&R ( remove and replace) costs and prop overhauls, all which are typically done at TBO.

I know many of you may look at the cost to operate your airplanes like we usually look at beer money and I am not suggesting we should only look at owning an airplane in financial terms. With that said, understanding the long term financial impact of your aircraft operation can reduce your ownership and operating costs and help you get the most bang for your aviation buck.